TL;DR:

Original Equipment Manufacturers (OEMs) in the automotive sector prioritize Repair Specification Compliance (RSC) for safety, performance, and vehicle longevity. Adhering to precise standards ensures technicians use approved methods, tools, and materials during repairs like frame straightening and paint application. Strict compliance preserves structural integrity and cosmetic appeal, avoiding discrepancies that could cause functional issues or potential safety hazards. Strategies to enhance RSC include comprehensive training, advanced digital tools for repair documentation, and robust quality control measures.

In the precision engineering sector, Original Equipment Manufacturer (OEM) accuracy is paramount. Repair Specification Compliance plays a critical role in ensuring these high standards are met. This article delves into the intricacies of this concept, exploring how adhering to repair specifications directly impacts OEM precision and product quality. We’ll uncover strategies to enhance and maintain compliance, highlighting best practices for continuous improvement in this vital process. Understanding and optimising repair specification compliance is a game-changer for maintaining excellence in manufacturing.

- Understanding Repair Specification Compliance

- The Impact on OEM Accuracy

- Strategies to Enhance and Maintain Compliance

Understanding Repair Specification Compliance

Repair Specification Compliance (RSC) is a critical aspect that Original Equipment Manufacturers (OEMs) cannot afford to overlook. It refers to the adherence to precise standards and guidelines during the repair process, ensuring that every replacement part and technique aligns with the manufacturer’s original specifications. This is particularly important in the automotive industry where maintaining accuracy in car body repair or auto bodywork is essential for safety, performance, and vehicle longevity.

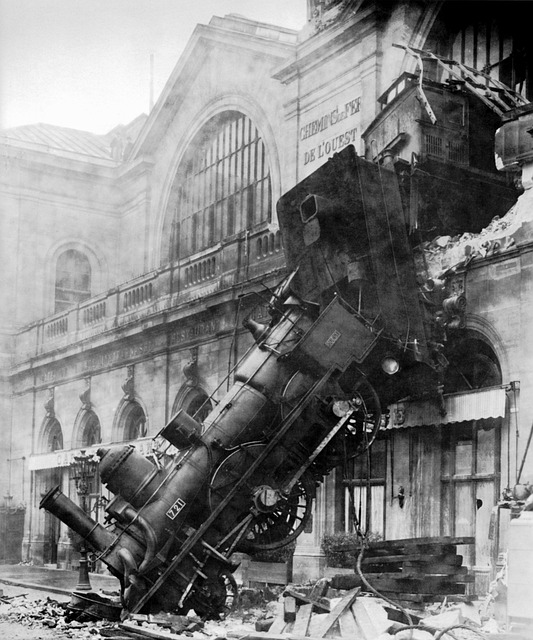

When an OEM sets repair specifications, they detail step-by-step procedures for various tasks, including frame straightening, panel replacement, and paint application. Compliance ensures that technicians follow these instructions to the letter, using only approved tools, materials, and methods. This level of precision is vital when fixing car dents or any other damage, as deviations from the specification could compromise structural integrity, cosmetic appeal, or both. RSC promotes consistency in repairs, guaranteeing that each vehicle returns to its original state, with all components functioning optimally.

The Impact on OEM Accuracy

When it comes to Original Equipment Manufacturer (OEM) accuracy, repair specification compliance is paramount. Adhering to the precise guidelines and standards set by vehicle manufacturers ensures that any repairs or replacements are done with precision and consistency. This is crucial in maintaining the integrity of the vehicle’s original design, performance, and safety features. Any deviation from these specifications can lead to discrepancies, compromising both the functionality and overall OEM accuracy.

In the realm of auto maintenance, especially after an auto collision repair or dent removal, strict compliance with repair specifications becomes even more critical. These processes often involve intricate details, from panel fitting to paint matching. Skimping on adherence to these specifications can result in visible imperfections, reduced structural integrity, and potential safety hazards. Thus, ensuring that every step of the repair process aligns perfectly with OEM guidelines is essential for both consumer satisfaction and vehicle longevity.

Strategies to Enhance and Maintain Compliance

Strategies to Enhance and Maintain Repair Specification Compliance are essential for achieving OEM accuracy in auto frame repair, vehicle dent repair, and auto dent repair processes. Companies should invest in comprehensive training programs for their technicians. This ensures they understand the intricacies of each repair specification, enabling them to accurately follow guidelines during every job. Regular workshops and updates on changes in repair standards further keep teams informed and adept at adhering to current practices.

Additionally, utilizing advanced digital tools designed for repair documentation can significantly streamline compliance efforts. These systems automate data entry, reduce human error, and provide immediate access to up-to-date specifications. Implementing robust quality control measures, such as random spot checks and peer reviews, also reinforces adherence to the standards. Together, these strategies ensure that every repair, regardless of complexity, is executed with precision and meets the stringent requirements set by OEMs.

Ensuring repair specification compliance is paramount for Original Equipment Manufacturers (OEMs) to maintain accuracy and precision in their products. By adhering to strict standards, OEMs can guarantee that replacement parts accurately mirror the design and performance of original equipment, fostering customer satisfaction and trust. Implementing robust strategies to enhance and maintain compliance is a continuous process that requires ongoing vigilance and adaptation to evolving industry standards. This commitment not only safeguards product integrity but also strengthens the OEM’s reputation in the market.